Measurement of Steam Flowrate using Clamp-on Ultrasonic Flowmeter

Purpose

|

To achieve efficient energy management in industrial plants, it is crucial to measure the steam flow rates at the various points of consumption.

Clamp-on time-of-flight ultrasonic flowmeters are useful devices to measure the steam flow rates in existing pipes.

However, it is difficult to accurately measure the steam flow rates because of the large acoustic impedance difference between the pipe material and fluid, strong signal attenuation in the fluid, and high temperature.

In addition, the steam wetness increases with heat losses and the presence of liquid film and droplets that creates noise in the detected ultrasonic signals, making it difficult to distinguish the target signals from the noisy ones.

The objective of this study is to develop a clamp-on ultrasonic flowmeter for wet steam flow. A new signal processing method, ultrasonic transducers, and the measurement system have been developed.

Research content

|

|

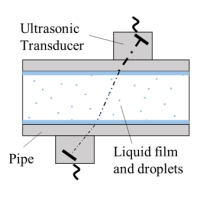

The presence of liquid films and droplets due to the steam wetness may alter the propagation paths of the ultrasonic signals emitted from the transducers, leading to noisy signals.

Fluctuations at the liquid-gas interface also leads to signal reflections and some of the reflected signals are transmitted through the pipe wall as guided waves.

This creates noise in the detected ultrasonic signals, making it difficult to distinguish the target signals from the noisy ones and thus, it is not possible to accurately determine the transit time difference and steam flow rate.

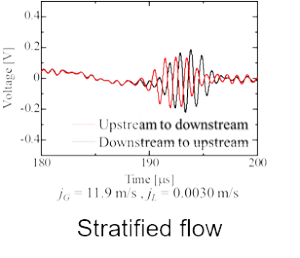

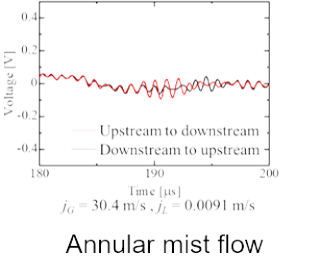

Experiments were carried out for air-water two-phase flows in a horizontal

pipe. The figures show the difference of the transmitted signal in stratified

and annular mist flows. It was found that intensities of the transmitted

signal strongly depends on the flow regime. Furthermore, standard deviations

of the transmitted ultrasonic signals are newly proposed for the time-of-flight

analysis. Furthermore, the developed techniques have been applied to measurements

of wet-steam flows.

Publications

H. Murakawa, S. Ichimura, K. Sugimoto, H. Asano, S. Umezawa, H. Taira, M. Ibi, H. Akahane

Measurement of steam flow rates using a clamp-on ultrasonic flowmeter with various wetness fractions, Flow Measurement and Instrumentation 80, 101997(2021). https://doi.org/10.1016/j.flowmeasinst.2021.101997

H. Murakawa, S. Ichimura, M. Shimada, K. Sugimoto, H. Asano, S. Umezawa, K. Sugita

Effect of incident angle on ultrasonic transmission in steam flow for use with clamp-on ultrasonic flowmeter, Mechanical Engineering Journal 7(4), 20-00131 (2020). https://doi.org/10.1299/mej.20-00131

H. Murakawa, S. Ichimura, K. Sugimoto, H. Asano, S. Umezawa, K. Sugita

Evaluation method of transit time difference for clamp-on ultrasonic flowmeters in two-phase flows,

Experimental Thermal and Fluid Science 112 (2020) 109957. https://doi.org/10.1016/j.expthermflusci.2019.109957

Back